How Processing Techniques Shape Leather Performance and Sustainability

Share

The performance, aesthetics, and environmental footprint of leather products are not solely determined by the raw material itself, but largely by the techniques used to process the leather. From traditional vegetable tanning to modern chrome tanning and finishing methods, each stage of leather production significantly influences both the physical characteristics of the final product and its impact on the environment. In an era where sustainability is becoming increasingly important, understanding how leather processing techniques affect performance and ecological responsibility is essential for manufacturers, designers, and conscious consumers alike.

At the heart of leather processing is the tanning process, which stabilizes the collagen structure in animal hides to prevent decomposition and prepare the material for long-term use. Two of the most widely used tanning methods—chrome tanning and vegetable tanning—produce leathers with vastly different attributes.

Chrome tanning, a chemical-intensive process developed in the 19th century, is currently the most common method used worldwide. It involves treating hides with chromium salts, which rapidly alter the protein structure to create a soft, flexible, and water-resistant leather. This method is efficient and cost-effective, taking just a day or two to complete. Chrome-tanned leather is ideal for mass production and products that require pliability, such as apparel and upholstery. However, its environmental impact is a major concern. Improper handling of chromium waste can lead to soil and water contamination, and some forms of chromium compounds are toxic to both humans and ecosystems. While some tanneries have adopted cleaner practices and use safer trivalent chromium, the overall sustainability of chrome tanning remains limited.

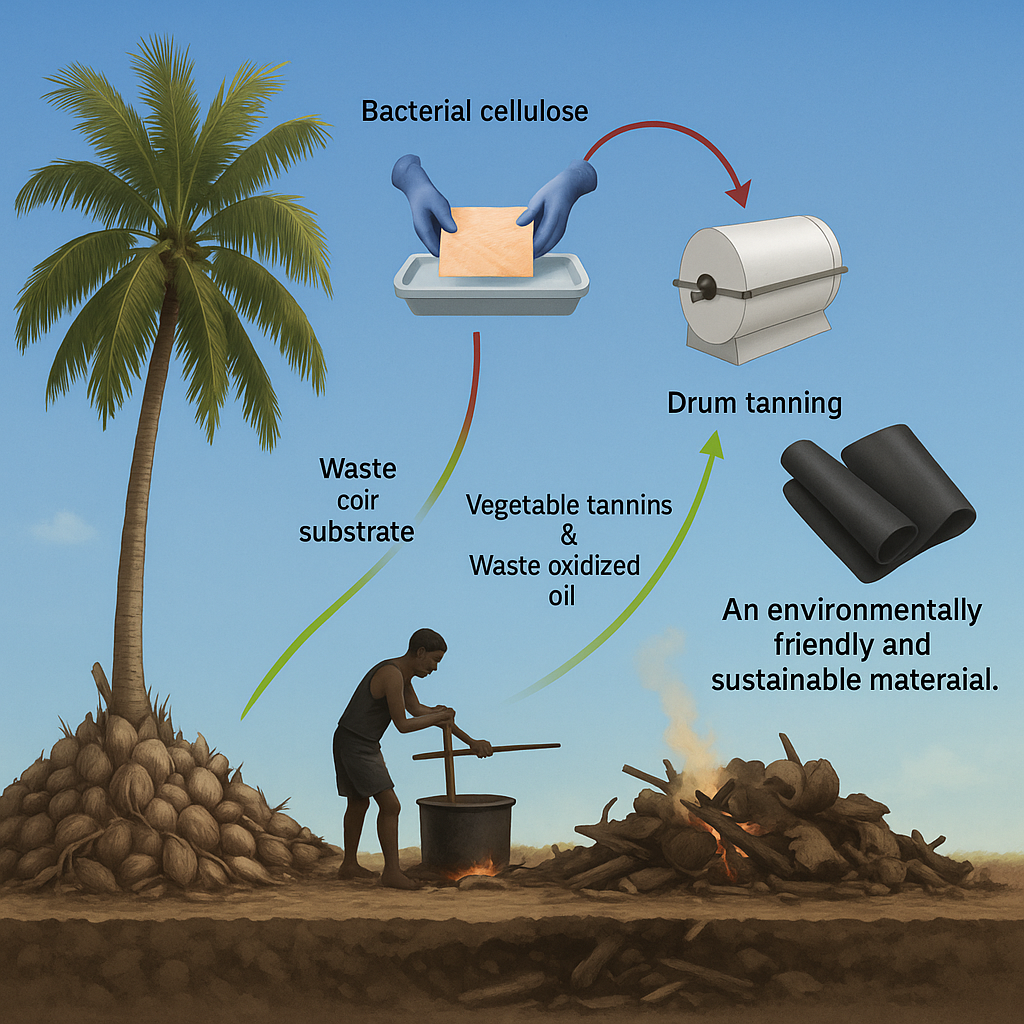

In contrast, vegetable tanning uses tannins extracted from plant materials such as tree bark, leaves, and roots. This traditional technique is slower—taking several weeks—but results in a firmer, more structured leather that develops a natural patina over time. Vegetable-tanned leather is highly valued for its durability and character, especially in applications like belts, bags, and artisanal goods. More importantly, this method is significantly more sustainable. The absence of harmful chemicals in the tanning process reduces the risk of environmental pollution and produces leather that is more biodegradable at the end of its life cycle.

The choice of tanning method also affects the performance characteristics of leather. Chrome-tanned leather is more elastic and has greater resistance to high moisture conditions, making it suitable for dynamic and humid environments. Vegetable-tanned leather, while less flexible, excels in applications that demand longevity, firmness, and a natural appearance. The performance-to-environment trade-off between these two methods is often the deciding factor for manufacturers and designers aiming to align functionality with sustainability.

Beyond tanning, finishing processes also influence the final quality and environmental footprint of leather. Techniques such as dyeing, embossing, waterproofing, and coating are used to enhance the appearance, texture, and durability of leather. Many conventional finishing methods rely on petroleum-based chemicals, synthetic resins, and heavy metals that can compromise leather's biodegradability and release harmful volatile organic compounds (VOCs). In response to growing environmental concerns, innovations in water-based finishes, low-impact dyes, and plant-derived waxes are offering more eco-conscious alternatives without sacrificing quality.